Solving Thermal Grease Issues by Using Graphite TIM

Solving Thermal Grease Issues by Using Graphite TIM

2019-04-15

Introduction

TIMs (thermal interface materials) are materials used to fill gaps between heat-generating components and heatsinks to

reduce the contact thermal resistance in order to increase heat dissipation effects. Although thermal greases are the

most commonly used TIMs, they have several issues.

This article will introduce a problem solving case example for power modules used in power conversion applications, such

as inverters, by replacing the TIM from thermal grease to Graphite TIM.

Thermal Management Using Thermal Greases and Their Issues

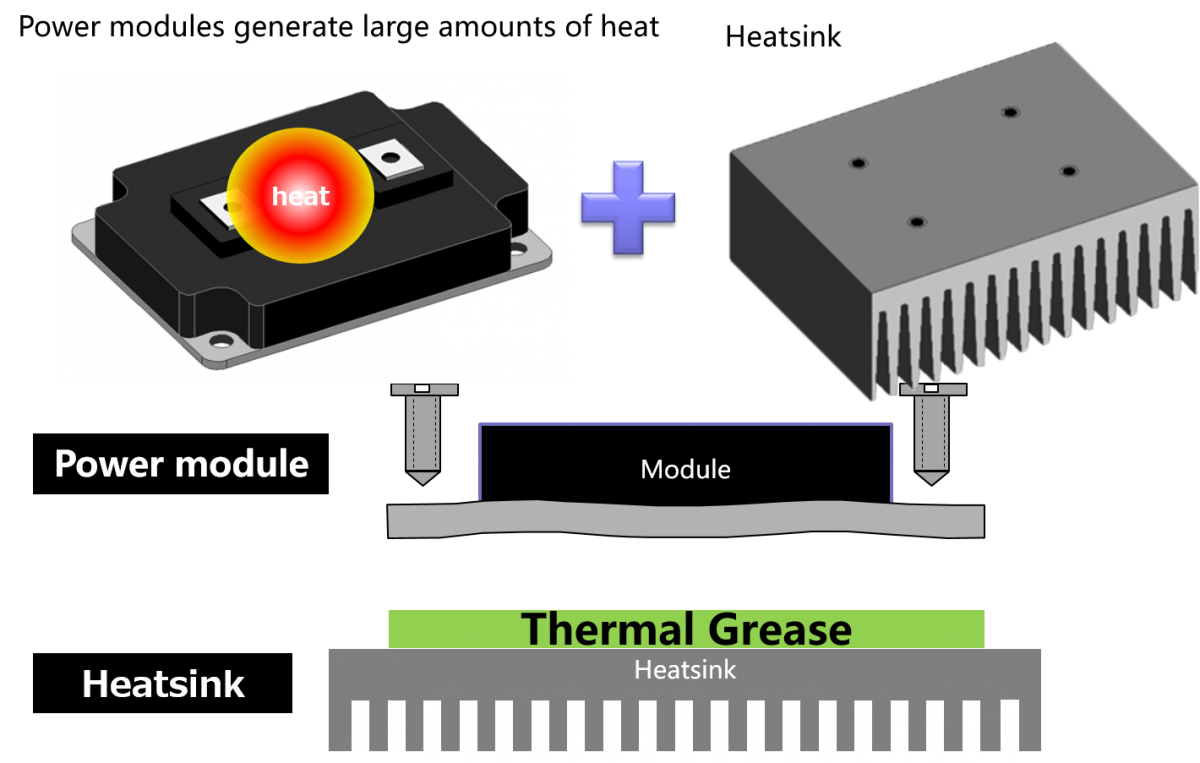

Power modules, which generate large amounts of heat, are usually connected to heatsinks, etc., to dissipate heat. When

mounting a heatsink on a power module, joining them as they are will inevitably create gaps between the base plate and

heatsink because the base plate is slightly distorted. As a result, the dissipation effects of the heatsink cannot be

fully obtained due to the contact thermal resistance caused by inadequate adhesion.

As a countermeasure, as shown in the diagram below, a thermal grease is applied between the base plate and heatsink as a

TIM to fill the gaps to reduce the contact thermal resistance, thereby improving the dissipation effects.

-

- Thermal resistance variations due to voids

- Gaps may not be completely filled because of the application amount and uniformity of thermal greases, and the resulting voids may cause the inadequate reduction in contact thermal resistance.

-

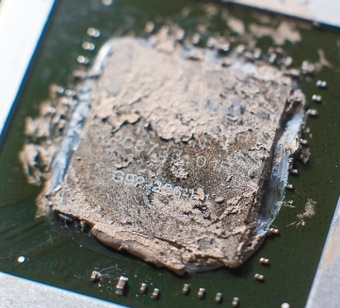

- Increase in thermal resistance due to dryout phenomenon

- The dryout phenomenon refers to a condition whereby the components of thermal greases evaporate due to heat, separating oil and filler. When greases degrade due to dryout, they become hard and crack, increasing the contact thermal resistance.

-

- Increase in thermal resistance due to pump-out phenomenon

- The expansion/contraction of base plates during long-term use causes the pump-out phenomenon in which greases are gradually discharged. The greases become thinner due to this phenomenon, creating gaps that result in an increase in the contact thermal resistance.

Dryout phenomenon

Pump-out phenomenon

-

- Increase in total costs

-

It is also necessary to implement periodic maintenance (disassembly → cleaning → application → assembly) to address

performance degradation due to dryout and pump-out phenomena.

Therefore, although thermal greases themselves are cheap, total costs are high.

Problem Solving Case Example by Using Graphite TIM

By using Graphite TIM (graphite-based thermal conduction sheet) instead of a thermal grease, the thermal grease issues listed above can be resolved. Graphite TIM, which is a sheet-like part material with excellent thermal conductivity, is a Panasonic TIM sandwiched between heating elements and heatsinks. Although a Graphite TIM needs to be sandwiched with adequate pressure to obtain favorable thermal characteristics, it is very easy to install and handle and has excellent reliability. The table below summarizes the features of thermal greases and Graphite TIM.

| Thermal grease issues | Thermal conduction sheet Graphite TIM |

|---|---|

| ① Thermal resistance variation due to voids | Absorbs differences in level through its high compressibility, achieving a stable thermal resistance equivalent to that of thermal greases. |

| ② Increase in thermal resistance due to the dryout phenomenon | Heat-resistant to temperatures over 400ºC; no degradation due to heat |

| ③ Increase in thermal resistance due to the pump-out phenomenon | Physical properties remain unchanged semi-permanently. |

| ④ Increase in total costs |

Easy installation that only requires placement and simple maintenance ⇒ Low total costs |

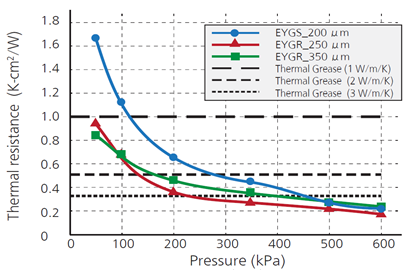

The graph on the right shows changes in the thermal resistance of Graphite TIM in accordance with the pressure.

It shows that the thermal resistance decreases when higher pressure is applied to sandwich a Graphite TIM, and the

Graphite TIM indicates a thermal resistance equivalent to that of thermal greases in high compression areas. This

indicates that Graphite TIM can be used as a substitute for thermal greases without any problems.

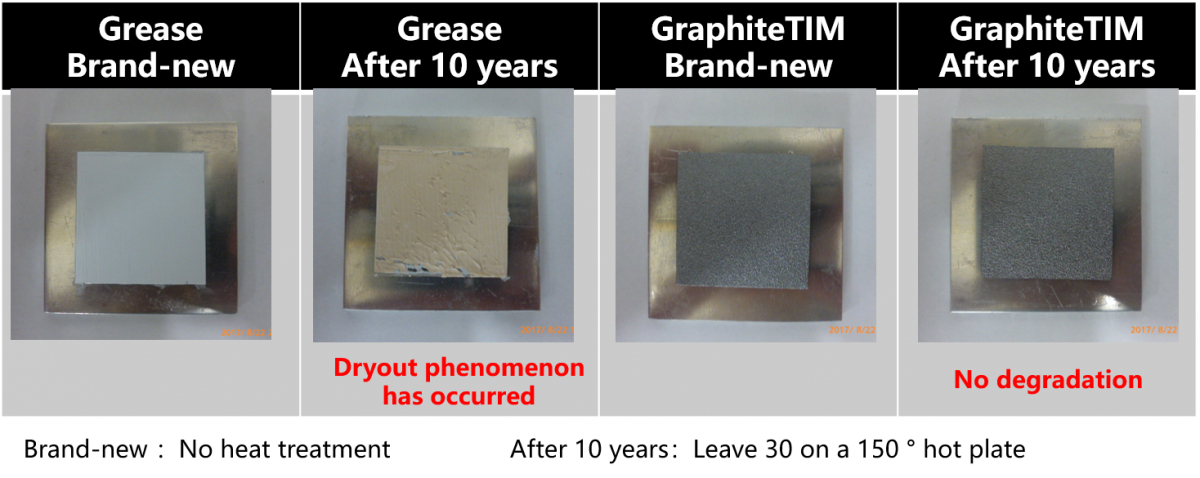

The results of a test that assumes dryout due to heat are also shown below. The photos show brand-new states and states after being left on a 150ºC hot plate for 30 minutes as an acceleration test to simulate a 10-year period. No degradation due to heat was observed with Graphite TIM, indicating that dryout issues can be resolved.

Summary

Thermal greases are TIMs with a long history and have been widely used in various areas. However, they have issues related to reliability and total costs. The thermal conduction sheet Graphite TIM has excellent performance and high reliability as a substitute for thermal greases and can therefore resolve the issues with thermal greases.

Related product information

Tags related to this article

This content makes every effort to ensure the accuracy, completeness, and usefulness of the provided information, but does not provide any kind of warranty.

The information presented is current as of the publication date and may be subject to future changes and updates.