Topics

- 2023-09-29 ERJL1W series has been discontinued.

- 2022-11-01 Sensing Resistors Thick Film Type(ERJL1W series) are Not Recommended for New Design.

- 2021-04-01 Metal Plate Type-MS6S has been discontinued.

- 2021-04-01 Metal Plate Type-MP has been discontinued.

- 2021-04-01 Metal Plate Type-M has been discontinued.

- 2021-04-01 Metal Foil Type has been discontinued.

- 2019-06-03 Metal Foil Type are Not Recommended for New Design.

- 2019-06-03 Metal Plate Type-MS6S are Not Recommended for New Design.

- 2019-06-03 Metal Plate Type-MP are Not Recommended for New Design.

- 2019-06-03 Metal Plate Type-M are Not Recommended for New Design.

- 2019-05-29 A brochure of high performance chip resistors has been posted.

- 2019-01-29 "Current Sensing Chip Resistors" page has been updated.

- 2018-09-03 "Low TCR High Power Current Sensing Resistors, Wide Terminal Type" have been commercialized.

- 2018-01-22 The Current Sensing Resistors, Metal Foil Type has been commercialized.

- 2017-02-22 The chip resistor line-up is divided into 5 categories.

(High Precision, Current Sensing, Small & High Power, Anti-Sulfurated and General Purpose) - 2016-10-28 Registration certificates of quality and environment certifications (ISO, TS) are available for download

- 2016-07-24 "Cross reference" has been posted

* Please read before use.

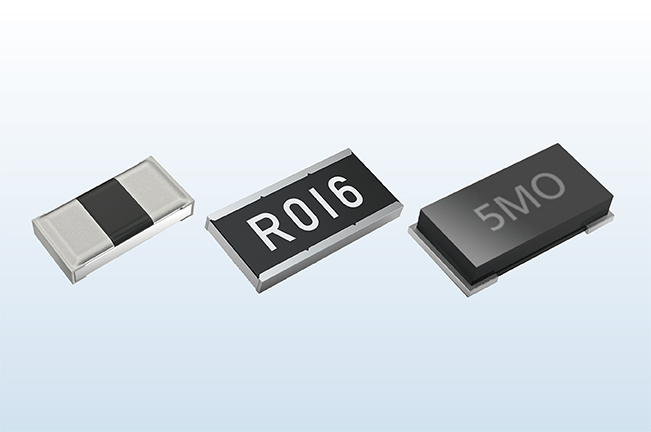

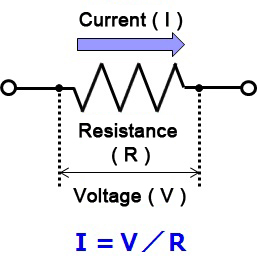

What is the current sensing resistor?

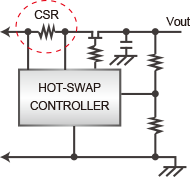

In electronic equipment, detecting current in the circuit and controlling it is very important for achieving higher performance, improved safety and better energy consumption. A current detection resistor is a component used for converting circuit current to voltage with a minimum loss of power. Among the variety of applications, three types of the principal use are shown below.

① Excess Current Detection

When an abnormal large amount of current flows through a circuit due to a failure or overload, current detection is required for actions such as stopping the circuit operation.

② Current Control

Peak current detection of an inductor for controlling the maximum output current of a DC/DC converter, current detection for phase and time control for driving a 3-phase motor, etc.

③ Current Management

Current management (Remaining battery power detection, etc.) of secondary battery-driven equipment such as smartphones and electric vehicles.

Features of Panasonic Industry products

At Panasonic Industry, we are developing current detection chip resistors in response to the heat generation caused by a larger current consumption in electronic equipment. For suppressing heat generation and loss, we promote “lower resistance” and “improved heat dissipation performance”. In addition, for maintaining the change of the resistance value to the minimum through temperature changes, we are “improving temperature coefficient (TCR)”.

Lower resistance

Panasonic Industry has proposed to reduce heat generation of a resistor by developing a current detection chip resistor with a lower resistance value and using it. The specific measures are as follows

- <Thick film type>

-

- Structure of using resistance film on both sides of a substrate and making the product shape rectangular to achieve lower resistance.

- Changing the resistance material from AgPd to a lower specific resistance value material CuNi.

- <Metal plate type>

-

- From the structure of printing resistance paste on a substrate to a newly developed structure of using a metal plate/foil as a resistance element. The new structure enables a thicker resistance element for covering a resistance rage of 5 mΩ or below. Not achievable by using the printed structure.

Improvement of Temperature Coefficient (TDR)

Accurate current measurement can be achieved by using a resistor with a smaller temperature coefficient because such resistors can maintain a small change of resistance value when temperature changes. For example, a smaller temperature coefficient reduces the error in the remaining battery charge of portable equipment, and enables extended operation with accurate control and management.

However, “lower resistance” and “lower temperature coefficient” are in a contradicting relationship, and reduced resistance presented the problem of increased temperature coefficient which reduced accuracy.

Panasonic Industry solved the problem by improving the material in the resistance element and electrode, and then commercialized current detection chip resistors with low resistance and low temperature coefficient.

Purposes of use of current sensing resistors

As the performance of battery-powered mobile equipment grows, the energy consumption is increasing, making it necessary to detect the amount of current used in circuits.

Current sensing resistors are intended to minimize the power loss and convert a circuit current to a voltage.

They are used for a variety of purposes as shown below.

Overcurrent sensing

Overcurrent sensing

○Power circuit protection from overcurrent

○Rechargeable battery protection

○Motor protection from overcurrent

Current control

Current control

○DC-DC converters

○Inverter power supplies

○AC motor current control

Management of currents

Management of currents

○Management of currents of rechargeable battery-driven devices for mobile equipment

○Management of currents of rechargeable batteries for hybrid cars

Applications

Panasonic Industry low resistance type resistors are being used, for example, in battery packs of laptop computers and mobile phones and in current control circuits in the automotive and industrial fields.

Your various requirements and purposes of use can be satisfied by our selection of products having excellent performance with a variety of resistance range, power, and temperature coefficient of resistance (TCR).

-

- Consumer equipment

-

- - LCD TV

- - Digital cameras

- - Gaming consoles

-

- Automotive equipment

-

- - Car navigation systems

- - Batteries

- - ECUs

-

- Communications equipment

-

- - Mobile phones

- - Base stations

-

- Industrial equipment

-

- - Industrial robots

- - Motors

-

- Computers

-

- - Laptops

- - Tablets

- - Printers