To draw a good thermal resistance from sheet, pressure the GraphiteTIM.

A close adherence would make the product fit into the uneven part and

enhance the performance.

Topics

- 2023-12-27 “Graphite-PAD” high thermal conductivity in z-direction has been discontinued.

- 2021-12-31 Some parts of PGS graphite sheet, SSM has been discontinued(24 part numbers).

- 2021-04-01 Some parts of PGS graphite sheet, SSM are Not Recommended for New Design (90 part numbers).

- 2020-09-23 The part number of GraphiteTIM has been added (250µm, 350µm).

- 2020-06-01 NASBIS are Not Recommended for New Design.

- 2019-12-02 Some parts of NASBIS are Not Recommended for New Design.

- 2019-12-02 Some parts of PGS graphite sheet are Not Recommended for New Design.

- 2019-07-11 The part number of Graphite-PAD has been added (6 part number).

- 2018-10-02 "GraphiteTIM" have been renamed to "GraphiteTIM".

- 2016-11-30 GraphiteTIM, a thermal interface material for power module, etc., has been commercialized

- 2016-11-30 The design support tool "IGBT-compatible GraphiteTIM Search Tool" has been posted

- 2016-10-28 Registration certificates of quality and environment certifications (ISO, TS) are available for download

Panasonic highly crystallized graphite, high reliability, easy installation,unprecedented thermal interface material

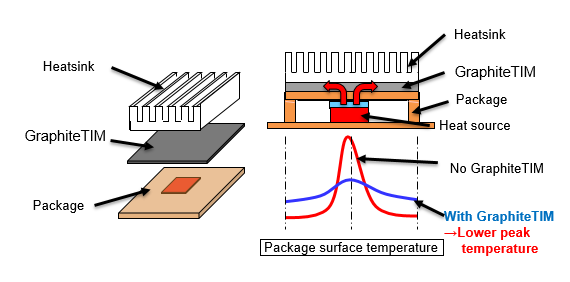

GraphiteTIM transfers heat generated from the power device to the heat sink with its excellent thermal interface material,

it is possible to extend the lifetime of the device and improve the work efficiency and contributing to total cost reduction.

*Note: Sound is included in this video

GraphiteTIM

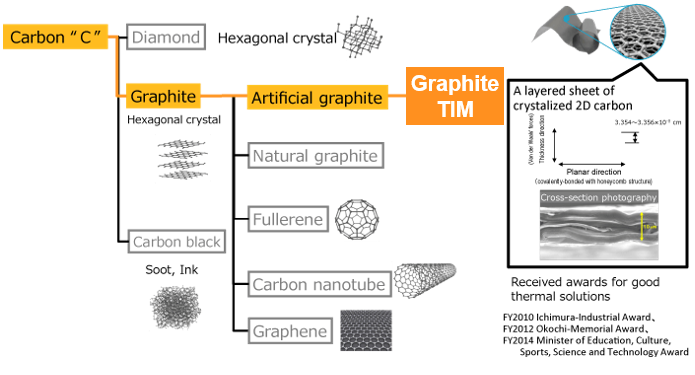

What is PGS Graphite sheets(GraphiteTIM)?

A type of graphite made from Carbon, an artificial flexible graphite sheet developed by Panasonic ⇒Merit factors: light weight, high intensity, high stability, low environmental impact

Basic functions of Thermal protection sheet

- 1. Heat transport

-

- 2. Thermal interface

-

How heat is transferred

-

GraphiteTIM reduces temperature rise

Use case

- <Power IC>

-

- <FET>

-

Features of GraphiteTIM

Feature

- Low thermal resistance

- High reliability

- Easy to handle

-

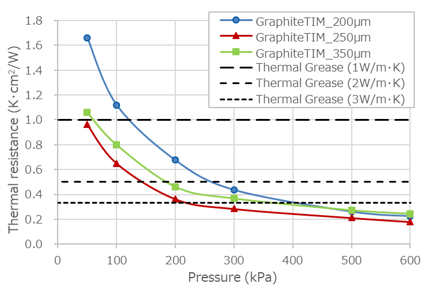

Low thermal resistance

GraphiteTIM provides as good low thermal resistance as grease even though sheet material.

■Thermal resistance compared to grease with different thermal conductivity

(Thickness of grease is 100 μm)

Measuring instrument: TIM Tester ( ANALYSIS TECH, ASTMD5470 compliant )

・Provide thermal resistance equivalent to grease.

-

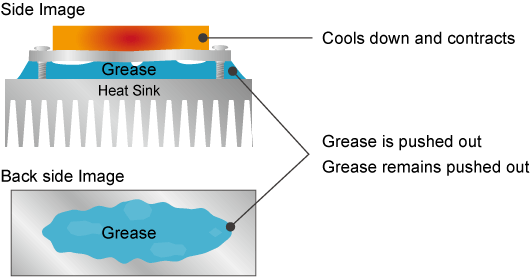

High reliability

GraphiteTIM maintains high reliability for a long period compared to a grease because of its property of hardly changing thermal resistance.

■Negative impact on the reliability due to pump out phenomenon

Pump-out test Heat cycle ( -40⇔100℃ ) Material Initial 120 times Deterioration

(Thermal resistance)Grease

Significantly deteriorated GraphiteTIM

Slightly deteriorated ・Pump-out does not occur and characteristic does not deteriorate much.

-

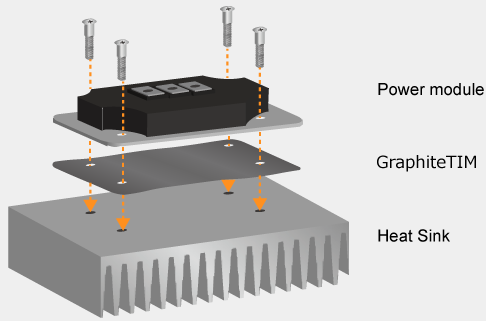

Easy to handle

GraphiteTIM is easy to handle and control, such as inventory control, repair, and processing, since it is a sheet type product.

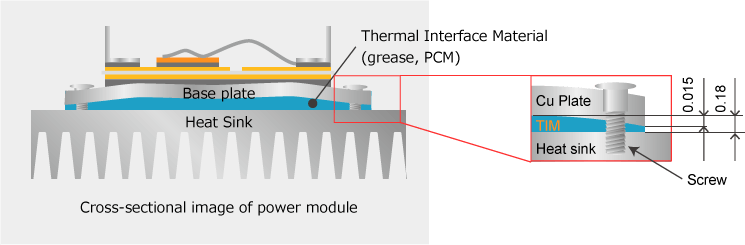

■All you need to do is fix with screws

・GraphiteTIM eliminates the need for an application process.

・Customization, such as hole making, and repair work are available.

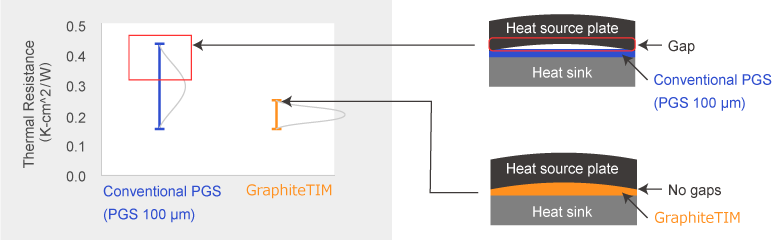

Reference: Comparison with conventional PGS

●Thermal resistance comparison

●Power module

・High compressibility property helps to reduce contact thermal resistance due to better fitting to uneven surface

Recommended applications

For cooling/heat transfer of electronic devices that generates heat, such as power module.

- Inverters and converters

- Car-mounted camera, motor control unit, automotive LED, luminous source of laser HUD, medical equipment

- Base station, Server

Other Thermal protection sheet lineup

-

- Heat transport

-

PGS

Graphite Sheet