- Compatible with high current applications by thick copper foil usage (70µm)

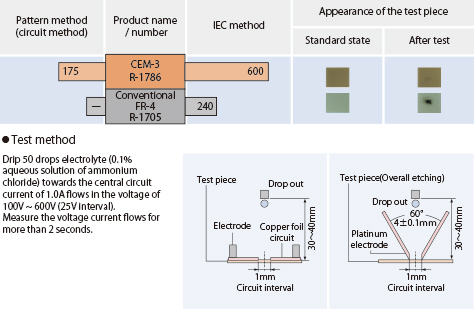

- CEM-3 grade material with high reliability (Tracking resistance CTI 600)

Circuit Board Materials

- Part Number

Double-sided

copper cladR-1786

- Application

- Detailed use

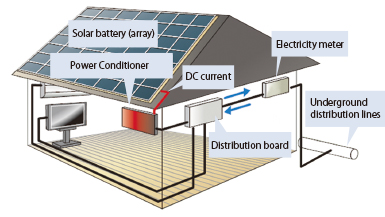

・For high current applications

Power supply system board, Inverter, converter board

Ex:power conditioner and battery of the solar power

Ex:power conditioner and battery of the solar power

Properties

High current

(Thick copper foil type)

(Thick copper foil type)

Tracking resistance

High reliability

Tracking resistance

General configuration of solar power(personal residence)

General properties

| Item | Test method | Condition | Unit | R-1786 | |

|---|---|---|---|---|---|

| Glass transition temp. (Tg) | TMA | Temp. rising rate: 10°C/min | °C | 140 | |

| Solder heat resistance | JIS C6481 | 260°C solder float for 2min | – | No abnormality | |

| Heat resistance | 1oz | JIS C6481 | A | – | 240°C 60min |

| CTE x-axis | α1 | IPC-TM-650 2.4.41 | TMA | ppm/°C | 25 (20) |

| CTE y-axis | 28 (23) | ||||

| CTE z-axis | α1 | IPC-TM-650 2.4.24 | TMA | ppm/°C | 65 |

| Dielectric constant (Dk) | 1MHz | JIS C6481 | C-96/20/65 | – | 4.2 |

| C-96/20/65+D-24/23 | – | 4.2 | |||

| 1GHz | IPC-TM-650 2.5.5.9 | C-24/23/50 | – | 4.0 | |

| Dissipation factor (Df) | 1MHz | JIS C6481 | C-96/20/65 | – | 0.011 |

| C-96/20/65+D-24/23 | – | 0.011 | |||

| 1GHz | IPC-TM-650 2.5.5.9 | C-24/23/50 | – | 0.007 | |

| Volume resistivity | JIS C6481 | C-96/20/65 | MΩ·m | 1×108 | |

| C-96/20/65+C-96/40/90 | 5×107 | ||||

| Surface resistivity | JIS C6481 | C-96/20/65 | MΩ | 3×108 | |

| C-96/20/65+C-96/40/90 | 1×108 | ||||

| Insulation resistance | JIS C6481 | C-96/20/65 | MΩ | 5×108 | |

| C-96/20/65+D-2/100 | 1×107 | ||||

| Water absorption | JIS C6481 | E-24/50+D-24/23 | % | 0.08 | |

| Flexural strength | Fill | JIS C6481 | A | N/mm2 | 280 |

| Peel strength | 2oz | JIS C6481 | A | kN/m | 2.2 |

| 260°C solder float for 20sec | 2.1 | ||||

| Alkali resistance | JIS C6481 | dipping (3min) | – | No abnormality | |

| Flammability | JIS C6481 | A+E-168/70 | – | 94V-0 | |

The sample thickness is 1.6mm.

The figure in parentheses is for the thickness of 0.8mm.

The above data are typical values and not guaranteed values.