- The new materials support 800GbE used for next-generation high-speed communication technology.

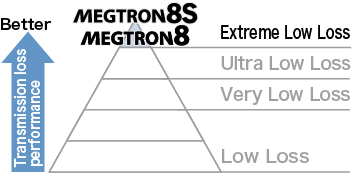

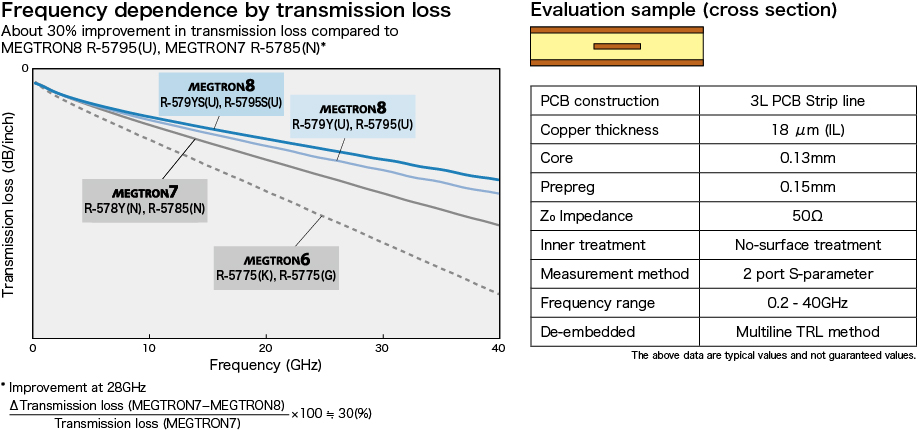

- Comparison of MEGTRON8 R-579Y(U), R-5795(U) and MEGTRON7 R-578Y(N), R-5785(N), improving transmission loss by about 30% (@28GHz) and contributing to improvement in the signal processing performance of high-speed communication networking equipment.

Circuit Board Materials

- Part Number

- Application

- Detailed use

・Network

・Wireless

・Wireless

Routers, Switches, Optical Transmission Equipment, Servers, AI Servers, Base Stations, Semiconductor Test Equipment, Probe Cards, etc.

New part number

Ultra-low Df glass cloth type

Laminate R-579YS(U)

Prepreg R-569YS(U)

Low Dk glass cloth type

Laminate R-579YS(N)

Prepreg R-569YS(N)

Existing part number

Ultra-low Df glass cloth type

Laminate R-5795S(U)

Prepreg R-5690S(U)

Low Dk glass cloth type

Laminate R-5795S(N)

Prepreg R-5690S(N)

New part number

Ultra-low Df glass cloth type

Laminate R-579Y(U)

Prepreg R-569Y(U)

Low Dk glass cloth type

Laminate R-579Y(N)

Prepreg R-569Y(N)

Existing part number

Ultra-low Df glass cloth type

Laminate R-5795(U)

Prepreg R-5690(U)

Low Dk glass cloth type

Laminate R-5795(N)

Prepreg R-5690(N)

- There might be some differences in UL certification conditions between the existing part numbers and the new part numbers. Please contact a sales representative in charge or this form for the detail.

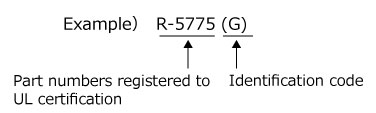

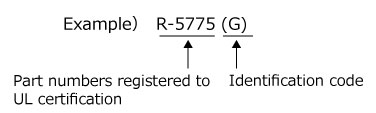

Any letters with parentheses ( ) at the end of a part number are for identification code in our company and are not included in the part numbers registered for UL certification.

Properties

Dk 3.08 Df 0.0012

@14GHz

@14GHz

Tg (DMA)

220°C

220°C

T288 (with copper)

>120min

>120min

Video

Transmission loss performance Ranking in MEGTRON series

Frequency dependence by transmission loss

General properties

| Item | Test method | Condition | Unit | MEGTRON8S R-579YS(U) R-5795S(U) Ultra-low Df glass cloth |

MEGTRON8S R-579YS(N) R-5795S(N) Low Dk glass cloth |

MEGTRON8 R-579Y(U) R-5795(U) Ultra-low Df glass cloth |

MEGTRON8 R-579Y(N) R-5795(N) Low Dk glass cloth |

|

|---|---|---|---|---|---|---|---|---|

| Glass transition temp.(Tg) | DMA | A | °C | 220 | 220 | 220 | 220 | |

| CTE z-axis | α1 | IPC-TM-650 2.4.24 |

A | ppm/°C | 35 | 35 | 50 | 50 |

| α2 | 240 | 240 | 270 | 270 | ||||

| T288(with copper) | IPC-TM-650 2.4.24.1 |

A | min | >120 | >120 | >120 | >120 | |

| Dielectric constant(Dk) | 14GHz | BCDR | C- 24/23/50 |

- | 3.19 | 3.22 | 3.08 | 3.13 |

| Dissipation factor(Df) | 0.0012 | 0.0015 | 0.0012 | 0.0016 | ||||

| Peel strength | 1oz (35µm) |

IPC-TM-650 2.4.8 |

A | kN/m | 0.7 [H-VLP3] |

0.7 [H-VLP3] |

0.7 [H-VLP3] |

0.7 [H-VLP3] |

The sample thickness is 0.75mm.

The above data are typical values and not guaranteed values.

series

series