- Leveraging multi-layer processability, low transmission loss, high thermal conductivity and Halogen-free, these materials are suitable for miniaturized and 5G small cell PCBs.

Circuit Board Materials

- Part Number

- Application

- Detailed use

・Wireless

・Automotive

・Automotive

Power amplifier board (Base station for wireless communication, Small cell), Antenna (Automotive millimeter-wave radar, Base station), etc.

New part number

Laminate R-5575X

Prepreg R-5470X

Existing part number

Laminate R-5575

Prepreg R-5470

- There might be some differences in UL certification conditions between the existing part numbers and the new part numbers. Please contact a sales representative in charge or this form for the detail.

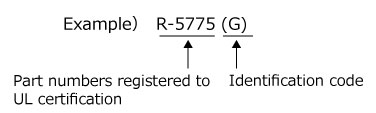

Any letters with parentheses ( ) at the end of a part number are for identification code in our company and are not included in the part numbers registered for UL certification.

Properties

Dk 3.60 Df 0.0045

@13GHz

@13GHz

Thermal conductivity

0.60W/m·K

0.60W/m·K

Tg (DMA)

245°C

245°C

Video

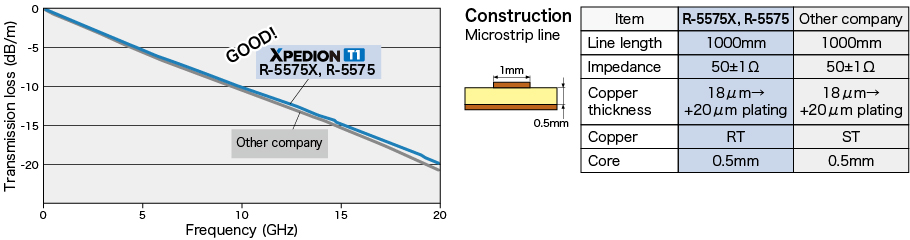

Frequency dependence by Transmission loss

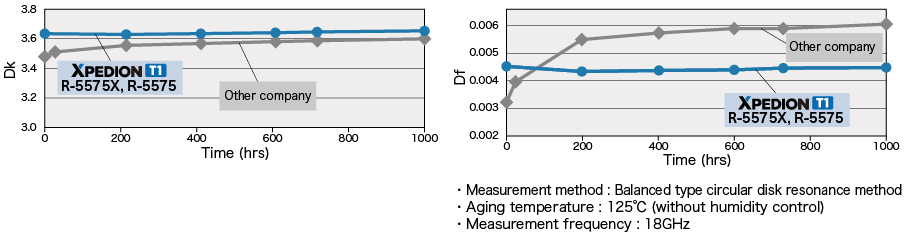

Long-term stability under High temperature(Dk, Df)

General properties

| Item | Test method | Condition | Unit | XPEDION T1 R-5575X R-5575 |

Other company | |

|---|---|---|---|---|---|---|

| Glass transition temp.(Tg) | TMA | A | °C | 205 | Tg less | |

| DMA | 245 | Tg less | ||||

| CTE z-axis | α1 | IPC-TM-650 2.4.24 | A | ppm/°C | 20 | 21 |

| α2 | 155 | 42 | ||||

| T288(with copper) | IPC-TM-650 2.4.24.1 | A | min | >120 | >120 | |

| Thermal conductivity | Laser flash | A | W/m·K | 0.6 | 0.6 | |

| Dielectric constant(Dk) | 13GHz | Balanced-type circular disk resonator method |

C-24/23/50 | - | 3.60 | 3.5 |

| Dissipation factor(Df) | 0.0045 | 0.004 | ||||

| Peel strength* | 1oz(35µm) | IPC-TM-650 2.4.8 | A | kN/m | 0.80 | 0.58 |

The sample thickness is 0.5mm

* RT Copper

Our Halogen-free materials are based on JPCA-ES-01-2003 standard and others.

Contain; Chlorine:≤0.09wt%(900ppm), Bromine:≤0.09wt%(900ppm),

Chlorine+Bromine:≤0.15wt%(1500ppm)

The above data are typical values and not guaranteed values.