- Felios adhesiveless flex materials are available in a wide-range of film and copper foil thicknesses to support all applications.

- Felios offers superior thermal resistance, dimensional stability and quality.

- Suitable for aerospace applications with low outgassing. (Compliant with ASTM E-595)

Circuit Board Materials

- Part Number

Double-sided copper clad

R-F775

Single-sided copper clad

R-F770

- Application

- Detailed use

・Aerospace

・Industry

・Automotive

・Industry

・Automotive

Consumer mobile products (Smartphone, tablet PC), Medical, Industrial, Avionics/Space applications, In-vehicle cable(Wire harness alternative), etc.

Properties

Superior thermal resistance

MOT 160°C

MOT 160°C

Wide line-up of film thickness

and copper foil

and copper foil

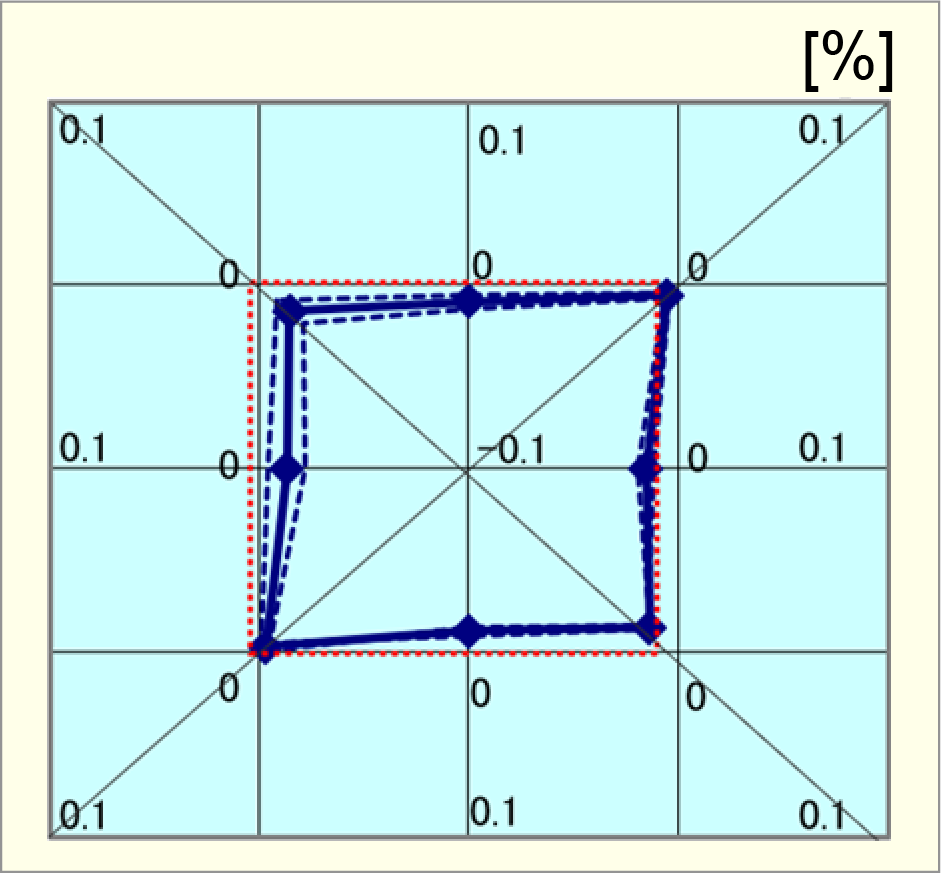

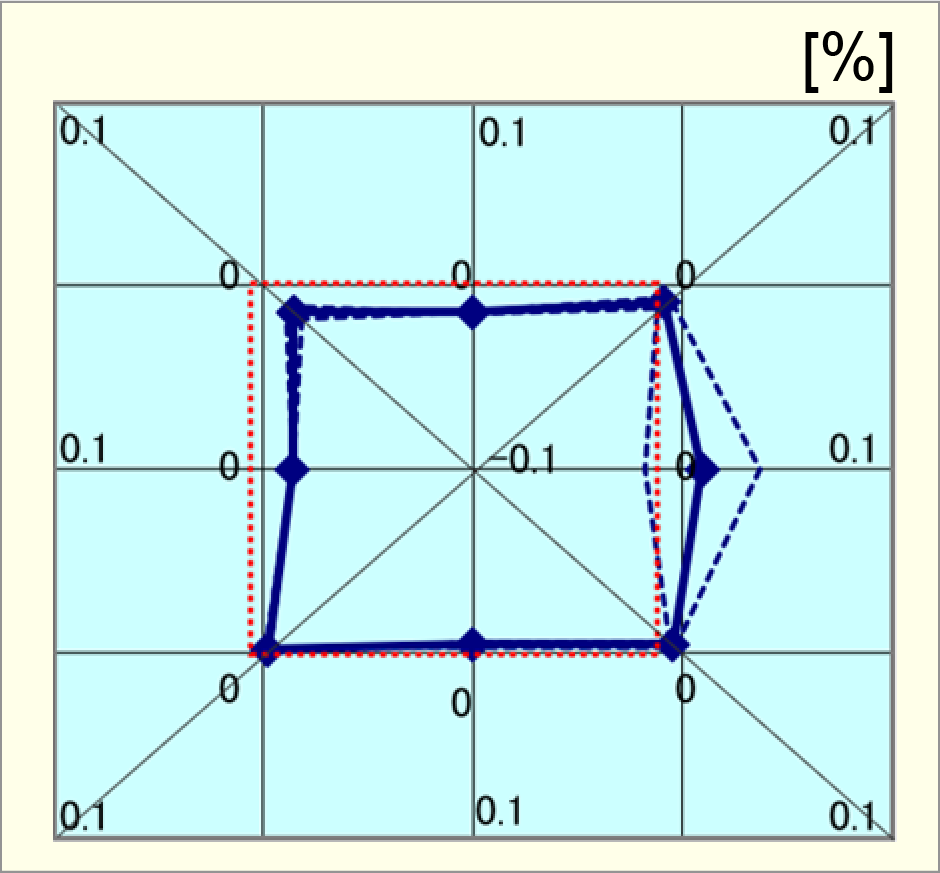

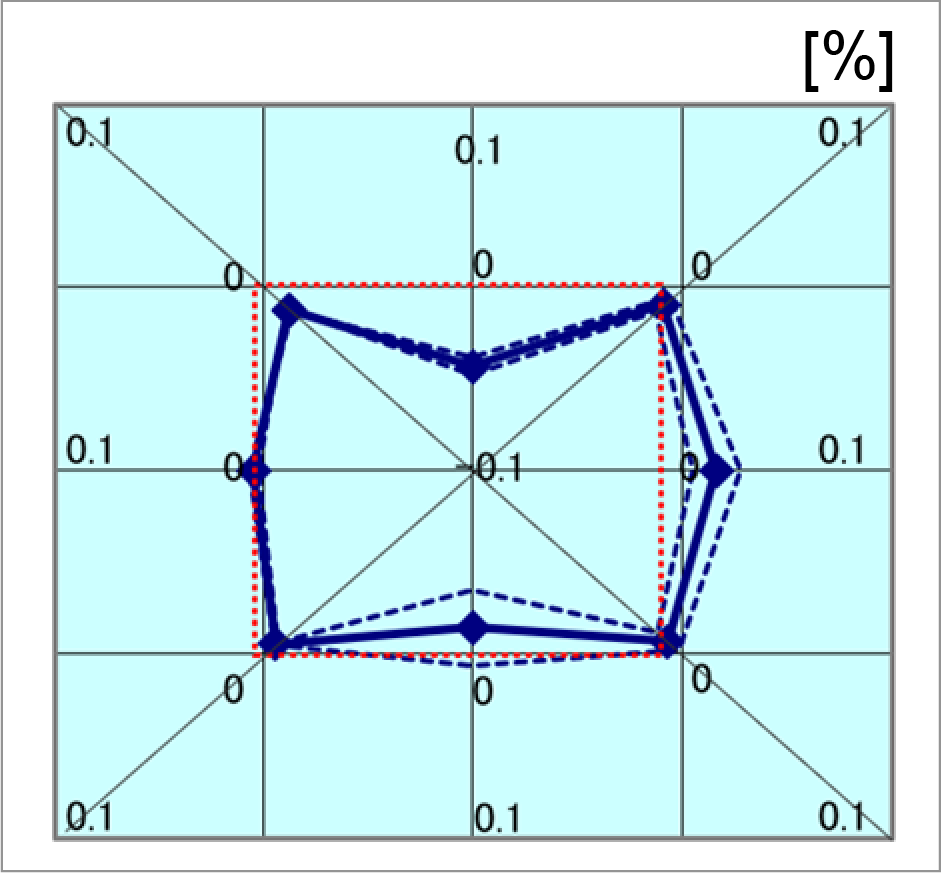

Excellent dimensional stability

Dimensional stability

Dimensional change after etching

Panasonic Industry FCCL materials

R-F775 After etching

Panasonic Industry FCCL materials

R-F777 After etching

Comparative material

After etching

Evaluation material is R18-100-R18, thickness 4mil.

The above data are typical values and not guaranteed values

Line-up

General properties

| Item | Test method | Condition | Unit | FELIOS R-F775 | |

| Solder heat resistance | IPC-TM-650 | A | °C | 280 | |

| C-96/40/90 | 240 | ||||

| Tensile Modulus | ASTM D882 | A | GPa | 7.5 | |

| Peel strength | RA: 1/2oz(18μm) | IPC-TM-650 | A | N/mm | >1.4 |

| CTE | MD-axis | TMA | 100°C→250°C 5°C/min | ppm/°C | 20 |

| TD-axis | 18 | ||||

| Dimensional stability | IPC-TM-650 | After etching MD direction | % | 0.00±0.10 | |

| After etching TD direction | 0.00±0.10 | ||||

| Outgas | TML / CVCM / WVR* | ASTM E595-07 ASTM E595-15 | - | % | 0.62 / 0.001 / 0.51 |

The sample thickness is film 50μm, copper foil 18μm.

* TML: Total Mass Loss

CVCM: Collected Volatile Condensable Material

WVR: Water Vapor Recovered

Our Halogen-free materials are based on JPCA-ES-01-2003 standard and others.

Contain; Chlorine:≤0.09wt%(900ppm), Bromine:≤0.09wt%(900ppm),

Chlorine+Bromine:≤0.15wt%(1500ppm)

The above data are typical values and not guaranteed values.